An in-depth understanding of heat transfer in rocks is critical for understanding geological sciences and underground engineering, for example, deep mining engineering, geological carbon storage, and improved geothermal systems. Rocks are multicomponent and multiphase geological porous media, and understanding their thermal conductivity is essential in understanding their heat transfer. The thermal conductivity of rocks is closely related to their mineralogical compositions, texture, pore structure, and fluids in the pores.

Several studies addressing the subject of rocks’ thermal conductivity have been published in recent years. The steady-state, transient optical scanning, and transient line-source are some of the methods used for testing the thermal conductivity of rocks. Also, several models for computing effective thermal conductivity of rocks have been extensively studied. They include harmonic, geometric, arithmetic, effective mean, among others.

The effective thermal conductivity of rocks is dependent on the thermal conductivity of the rock matrix, its porosity, and the fluid in the pores. The thermal conductivity of the matrix, whether in the dry state or saturated, should be an intrinsic value independent of the fluid in the pores. However, a significant deviation between the values of matrix thermal conductivity in the saturated and dry states has been reported. The reason behind this could be that the microstructural adjustments of the rock matrix during the dry-wet transition may have been ignored, particularly for rocks containing large amounts of swelling clay minerals. Some studies have suggested that the thermal conductivity of rocks is closely related to the hygroscopic features of the forming minerals, particularly when containing fluids.

Researchers Professor Pingye Guo, Dr. Mohua Bu, and Dr. Manchao He from China University of Mining and Technology and Dr. Yanwei Wang from China Institute of Water Resources and Hydropower Research measured the thermal conductivity, microstructure, and pore features of three categories of sandstones with varying clay mineral contents under natural, dry, wetting, and wetting-drying states. They analyzed the reason behind the change of effective thermal conductivity of the clay-bearing sandstone under the different states. The research article is published in the journal, Geothermics.

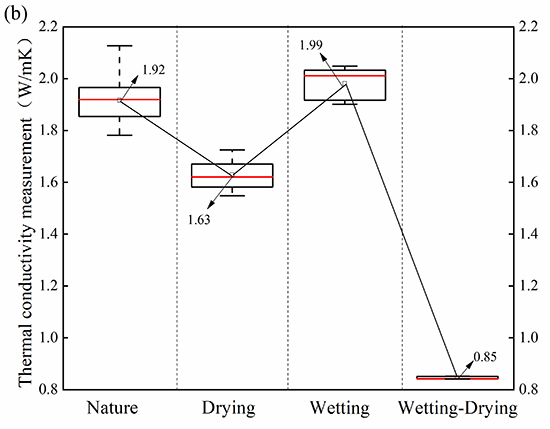

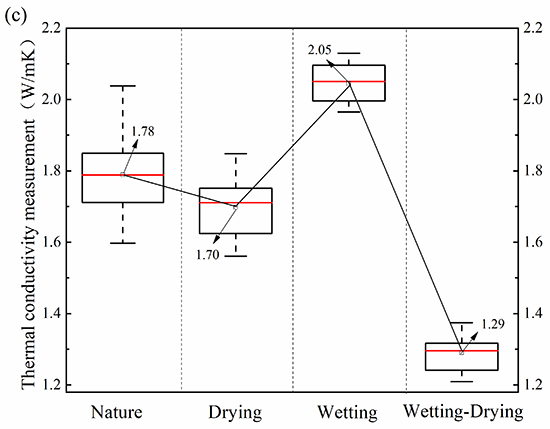

Sandstone samples with varying clay mineral content were subjected to drying, wetting and drying, and drying II treatment process, and their thermal conductivity was determined through the hot wire method. The sandstone samples were divided into three groups depending on their clay contents. Group I had the highest clay content at 55.61%, group II had the second-highest clay content at 40.81%, and group III had the lowest clay content at 19.61%.

The authors observed that the thermal conductivity in the wetting-drying state was much lower than that in the drying state irrespective of the sample’s clay mineral content. This shows that after undergoing the dry-wet process, the sample’s thermal conductivity changed significantly due to the effects of temperature and water. It was also observed that the difference in the thermal conductivity values between samples in the wetting-drying and drying state were related to their clay mineral content. Group I samples showed the largest thermal conductivity difference in the two states, followed by group II, and group III recorded the smallest. For group I, samples with the highest clay mineral content, thermal conductivity in the wetting state was slightly lower than in the natural state.

The thermal conductivity of sandstone samples subjected to drying treatment II was lower than that of samples under the drying treatment. The difference was related to the clay contents of the samples. Using an effective thermal conductivity calculation model that considers microcracks, it was observed that the large number of secondary cracks developed in the sample during the wetting-drying treatment was to blame for the decrease in thermal conductivity of the sample. Considering the microstructure and pore structure of the samples under the different states, dissolution of soluble minerals, swelling and shrinkage of clay, and disintegration of minerals were responsible for developing cracks during the dry-wet treatment process.

In a statement to Advances in Engineering, professor Pingye Guo said “The findings of this study provide insights into the effects of pore structure, fluids in the pores, and clay mineral content on the thermal conductivity of rocks. This understanding is crucial for various fields of study, including geological science, mining, hydrothermal systems, and underground coal gasification.”

(a) Thermal conductivity of Group Ⅰ

Guo Pingye, Ph.D. , A.P. at the School of Mechanics and Civil Engineering, China University of Mining and Technology-Beijing.

His research interests include rock mechanics, deep underground engineering and geothermal engineering. He is the PI of more than ten research projects, including those funded by the National Natural Science Foundation and the Ministry of Science and Technology. He has extensive design and consulting experience on some mine geothermal utilization projects. He has published more than 30 papers and holds 5 patents.

Reference

Pingye Guo, Mohua Bu, Manchao He, and Yanwei Wang. Experimental investigation on thermal conductivity of clay-bearing sandstone subjected to different treatment processes: Drying, wetting, and drying II. Geothermics, issue, 88 (2020), 101909.