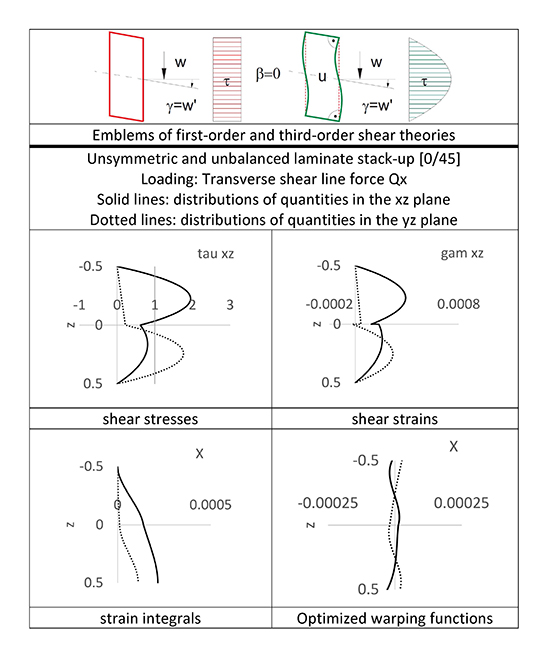

In material engineering, a composite laminate is a combination of fibrous composite materials (fibers in a matrix) that are bonded together layer-by-layer to obtain the required engineering properties, such as bending stiffness, strength, and in-plane stiffness. Generally, due to the anisotropy of unidirectional reinforced fiber matrix composites, the material shear stiffness may be lower than extensional stiffness along fibers by almost two orders of magnitude. Consequently, such material properties cause the transverse-shear deformations to contribute more to structural response of composite laminates than to that of homogeneous plates made from an isotropic material. Overall, the dominance of shear highlights the need for alternative methods to calculate transverse shearing strain and stress distributions, warping functions, and structural shear stiffness. In fact, under the premise of homogeneous force, or curvature-gradient, distribution, a solution for transverse-shear strains and stresses, warping functions, and through-thickness displacements can be derived by satisfying all relations and conditions of linear elasticity.

Adept research teams have investigated the problem of mapping shear effects in multidirectional laminates made from fiber-reinforced composites and sandwich design, and even presented several modeling approaches. However, a proper distinction must be made between point theories and structural theories. In this view, ETH Zürich researchers from the Laboratory of Composite Materials and Adaptive Structures: Dr. Gerald Kress and Mr. Daniel Thomas Filipovic, developed a novel point theory model by considering the response of moderately thick general laminates to spatially constant transverse cutting line forces. Their work is currently published in the research journal, Composite Structures.

In their study, the researchers considered a model that they developed under the assumption that interior transverse forces, or curvature gradients, remain constant. Ideally, the assumption rendered the model a point theory on the same range of applicability as the classical theory of laminated plates. Considering the assumption made, the theory calculated the exact solution of transverse-shear stresses and strains, warping functions, and transverse-shear-stiffness matrices. It was worth noting that the team was conscious of the fact that theories with a wider application range exist, that can approximate the effects of external distributed loads, or even of stress perturbation at boundaries and thus engaged in a comparative analysis later.

The authors reported that for the intended range of applicability, namely homogeneous interior force distributions, the theory was exact. Additionally, the researchers reported that as a layer-wise theory, their theory did not contain the errors inherent to the simple higher-order theories. Overall, predictions of the responses for a set of sample laminates of varying complexity, and comparison of stiffness values with those obtained by a dedicated FEM formulation, verified the model.

In summary, the study by ETH Zürich scientists successfully presented the derivation of a point-theory model for the transverse-shear response of arbitrary laminate or sandwich designs. Results for selected laminates, ranging in complexity from the simple unidirectional to the fully coupled, were also reported. In a statement to Advances in Engineering, Dr. Gerald Kress pointed out that their theory satisfies all conditions and relations of linear elasticity exactly. Even better, it delivers transverse-shear stress and strain distributions, cross-sectional warping functions, and the transverse shear stiffness matrix.

Gerald Kress, from Germany, studied mechanics at the Technical University Braunschweig, obtained a M.Sc. degree from the Virginia Polytechnic Institute (VPI), U.S.A. in 1983, and the degree of Dr.-Ing. from TU Braunschweig in 1992. His career includes positions as junior scientist at the German Aerospace Center DLR at Braunschweig and structural analyst at the former DORNIER SYSTEM GMBH, Friedrichshafen. From 1988 until his retirement in 2019 he worked as a senior scientist at ETH Zürich.

His research interests cover mechanical modeling, stress analysis and failure prediction of parts made from composite materials, the finite-element method as well as design-optimization methods. He founded and led research groups focusing on full-field optical measurement with speckle interferometry, computational structural mechanics, and composite structures. He obtained and led more than 25 funded research projects with the Swiss National Science Foundation, the Swiss Commission for Technology and Innovation, the Brite/Euram programme, and the European Space Agency ESA. Published work includes the topics of

- fatigue damage in notched CFRP laminates,

- edge effects and their impact on test-coupon stiffness and strength,

- structural optimization,

- FEM-modeling of progressive damage,

- local deformation behavior of sandwich structures with honeycomb core,

- substitute-plate modeling of corrugated laminates including transverse shear,

- simplified FEM modeling of helical structures,

- corrugated polymer diaphragms for pulsatile ventricular assist devices for the human heart, and

- kinematics of a new dielectric design of co-axial power cable for space applications.

He taught the courses “Structural Analysis with FEM”, “Structural Optimization”, “Mechanics of Composite Materials”, “FEM Programs” (Engineering Tools), and “Procedures of Structural Analysis”.

Daniel Thomas Filipovic obtained both his Bachelor’s and Master’s degree in Mechanical Engineering at ETH Zürich, writing his Master’s Thesis in the field of computational structural mechanics.

His main research interest lies in the efficient modelling of composite mechanics using numerical methods. Currently, he is working as a research assistant at the Laboratory of Composite Materials and Adaptive Structures (CMASLab) at ETH Zurich. In the course of his work, he is investigating the structural behavior and the manufacturing of corrugated laminates.

Reference

G. Kress, D. Filipovic. Exact model for the response of moderately thick laminates to transverse forces. Composite Structures, volume 227 (2019) page 111261.